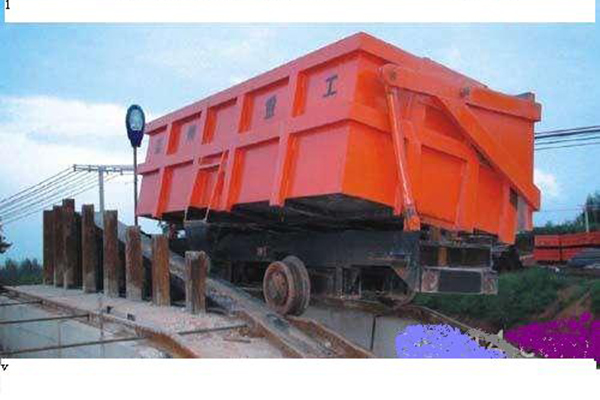

Side Dumping Mine Car is mainly used for tunneling, construction and transportation of metallurgy, mine tunnels, coal mines, railways, highway tunnels, underwater culverts, diversion tunnels, diversion tunnels, culverts, hydraulic tunnels, etc. 1. Equipment for slag transportation. The side-dumping mine car is driven by a traction locomotive or a winch, and can be combined with a rock drilling drill, a slag picker [stand-up claw rock loader] and an ore slip gate discharge system to load, the ore block size does not exceed 600 mm, according to The load volume of the mine car is led to the special curved track unloader [slag unloading platform] by the traction power (the running speed does not exceed 1m/sec) after loading. The electric locomotive or winch pulls the side dump mine car onto the prepared slope platform of the slag dump. When the electric locomotive or winch returns, the mine car automatically closes in place through the curved door, and the entire automatic transportation and unloading process is completed. Side dump type mine car is commonly known as curved track side dump type mine car and rollover type mine car. Its capacity is 2 cubic meters, 3 cubic meters, 4 cubic meters, 6 cubic meters, and 8 cubic meters.

The Side Dumping Mine Car is composed of the following components: 1. Car box, 2. Car underframe, 3. Wheel axle, 4. Unloading wheel, 5. Support spring 6. Buffer rubber spring and bumper. Among them, the connection between the car box and the car chassis is in the form of a hinge, so that the mine car can open a certain angle when passing the unloading station so that the ore can be unloaded smoothly.

1. The front and rear plates and side plates of the car box are welded with 10mm thick steel plates, and the grooved steel plates are used to reinforce the outer sides of the car; the wing plates are welded to the left and right side plates respectively, and the upper side is welded with angle steel Slotted, and the angle steel is connected to the grooved steel plate so that the car box will not be damaged under the harsh working environment.

2. Undercarriage. The bottom plate is made of 20mm thick steel plate, and the angle steel and steel plate are welded under the bottom plate, so that the bottom plate can withstand the impact force of the ore on the bottom plate during loading.

3. Wheel axle. The axle consists of axles and wheels.

4. Unloading wheel. It is used when the mine car unloads the mine. When the Side Dumping Mine Car passes the unloading station, the unloading wheel starts to work. It rolls along the curved track to open the floor of the mine car. After the ore is unloaded, the floor is closed and the machine returns to the loading state.

5. Buffer rubber spring and bumper. The buffer and the bumper are installed at both ends of the mine car, mainly composed of a buffer rubber spring, bumper, latch and single ring chain. It can ease the impact between Side Dumping Mine Car and reduce the impact force, extending the life of the vehicle.